PFAFF - 8312

New

Electronical flat-bed ultrasonic welding machine - long arm version "1000 mm"

Ultrasonic welding with the Seamsonic is a modern, innovative and economic alternative and complementary to conventional sewing technology. If assembling of laminates, clothing fabrics with high share of polymer and technical nonwovens is required and in particular to get, the use of the Seamsonic is the first choice.

Version PFAFF 8312 CS / cut&seal

The proved single-wheel solution was optimized by the use of steel-sonotrode. This will reduce wear and associated costs greatly. For our customers the fine C&S-seam with its high strength is the main argument to buy this class of machines.

Version PFAFF 8312 CS / cut&seal DUAL

This solution features two anvil wheels (one for cutting and sealing and the other one to realize the second weld seam) on one post, but on separate shafts. With this patented solution the load may be individually adjusted – the two wheels are still running in sync. This is an absolute unique selling point (USP) for this technology. The machine may be adjusted better and more specifically to the material at hand and increases the process reliability when welding and cutting to weld seams. The minimum distance between weld seam an cutting is around 1 mm.

Features

- Long arm version 1000 mm

- All parameters controlled electronically (power, amplitude, speed and pressure)

- Seam distances resp. operating cycles can be programmed (sequence welding)

- Reproducibility of the welding process

- The energy adjusts to the speed (via a pedal) = Dynamic welding

- Equipped with differential feed; separate drive for sonotrode and anvil wheel; that means smooth, non-distorted seams or the possibility of adding a some fullness

- Process reliability through monitoring of welding parameters with integrated device for constant performance (so that reliable processing is possible even when sewing over cross seams)

- Possibility of spot welding (tacking)

- No start/stop – marks

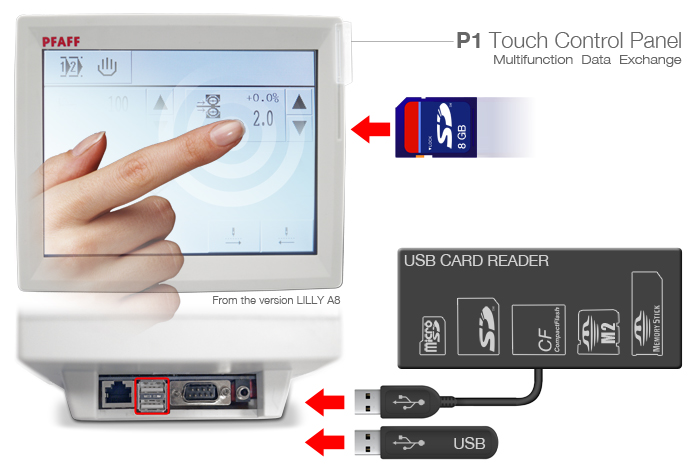

- Touch screen (simple handling with pictograms)

- Titanium sonotrode, up to 10 mm

- Hardened steel sonotrode, 7 mm

- Hardened steel sonotrode, 10 mm

- Welding method: 35 kHz, 400 W Ultrasonic generator

Applications

Specifications

Sealing speed: 0.5 to 10 m/min. option to 20m/min.

Seam width: 1,0 to 10,0 mm

Ultrasonic frequency: 35 KHZ

Connection voltage: single-phase a.c. 230 V, 50/60 Hz